Description

In the heart of every industrial combustion system, reliable operation hinges on two critical functions: igniting the fuel and proving the flame. Failure in either is not an option. It can lead to costly downtime, inefficient fuel consumption, and, most critically, catastrophic safety risks.

TriboMarket provides a comprehensive portfolio of industrial-grade Ignition and Flame Detection Electrodes engineered for precision, durability, and operational safety. Our components are the trusted “eyes and ears” of your Burner Management System (BMS), ensuring a stable spark for ignition and providing an unwavering signal for flame monitoring. Whether you are managing a power-generation boiler, a process heater, or a commercial furnace, our electrodes deliver the reliability your system demands.

The Critical Role of Ignition & Flame Detection

Modern combustion systems are built on a foundation of safety. An ignition electrode must reliably deliver a high-voltage spark at the precise moment required, while a flame detection electrode (or flame rod) must instantly confirm the presence of a stable flame.

The absence of a reliable signal from a flame rod forces the safety controller to shut off the fuel supply, preventing the dangerous accumulation of unburnt fuel. Conversely, a weak or failed igniter leads to start-up failure and system lockouts.

These components operate in the most hostile environments imaginable—exposed to extreme temperatures, thermal shock, corrosive byproducts of combustion, and high electrical stress. Using subpar components risks signal failure, carbon fouling, and material degradation. At TriboMarket, we source and supply only components that are proven to withstand these challenges, ensuring the integrity of your flame safeguard system and the safety of your personnel.

Our Comprehensive Range of Combustion Electrodes

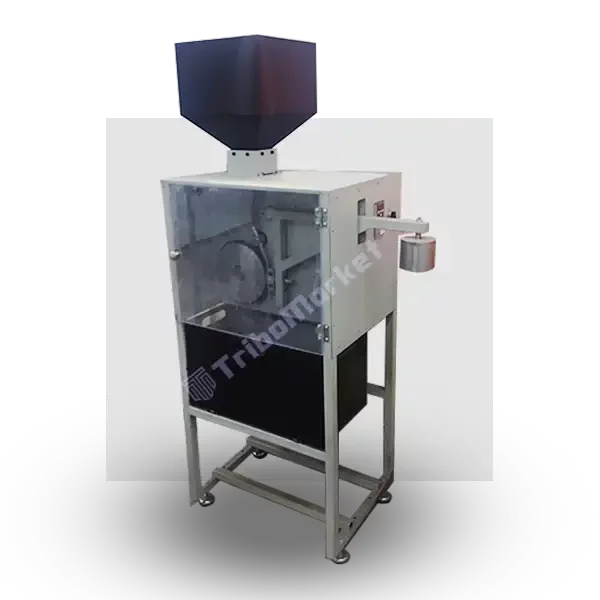

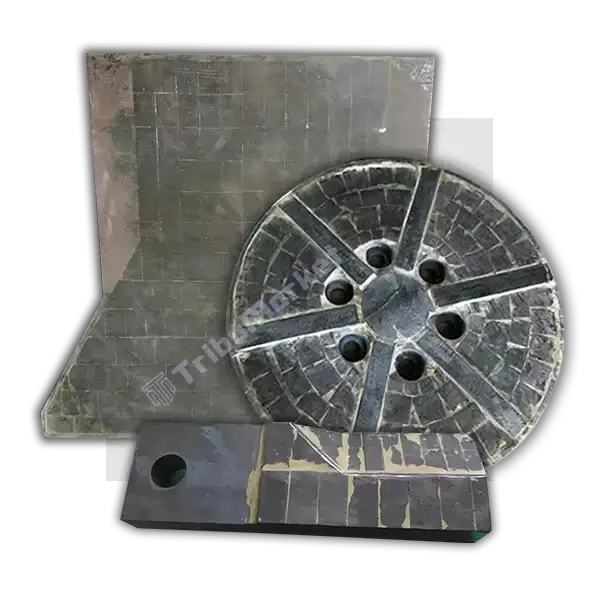

Our extensive inventory, as showcased in the product imagery, covers every application, from standard pilot assemblies to complex, multi-functional burner heads.

High-Reliability Ignition Electrodes

Designed to generate a consistent, high-energy spark, our ignition electrodes initiate combustion with unfailing reliability.

- Materials: We feature electrodes crafted from high-temperature alloys like Kanthal (FeCrAl) and Nickel-Chromium, which resist erosion and oxidation from the spark and heat.

- Insulation: The core of every igniter is its ceramic insulator. We utilize high-purity (95-99%) alumina ceramics, providing superior dielectric strength to prevent voltage arcing and exceptional resistance to thermal shock, which can cause cracking.

- Designs: Our selection includes everything from robust spark plugs (like NGK types) for heavy-duty engines and large burners to single-pin ceramic igniters for pilot lights and smaller appliances.

Precision Flame Detection Electrodes (Flame Rods)

Our flame detection rods operate on the proven principle of flame ionization. A controller applies an AC voltage to the rod; the flame itself ionizes the surrounding gases, acting as a rectifier to allow a micro-amp (µA) DC signal to flow back to the controller. This signal is the “proof” of a flame.

- Sensitivity: Engineered for maximum signal integrity, our flame rods provide a clear, stable signal that flame controllers can easily read, preventing “nuisance shutdowns.”

- Durability: The electrode material is designed to resist “flame-ashing” and chemical corrosion, which can create an insulating layer and weaken the signal over time.

- Configurations: We stock a vast array of single-rod sensors, dual-rod assemblies, and L-shaped rods, with various mounting brackets, lengths, and connectors to ensure a perfect fit for your burner geometry.

Integrated Ignition & Flame Sensor Electrodes

For modern, compact burner designs, we offer combined units that integrate both the ignition spark electrode and the flame detection rod into a single, pre-gapped assembly. This simplifies installation, reduces component count, and ensures perfect alignment between the spark and the flame-sensing area.

Key Features & Engineering Excellence

When you choose components from TriboMarket, you are investing in quality that pays dividends in uptime and safety.

- Premium-Grade Materials: Our electrodes are made from alloys chosen for their specific properties, ensuring maximum service life even in continuous-duty, high-temperature applications (up to 1400°C / 2550°F).

- High-Purity Alumina Insulators: We reject low-grade ceramics. Our components use high-purity alumina for its exceptional thermal and electrical properties, preventing cracks and shorts.

- Precision Manufacturing: Consistent and accurate electrode gapping is critical for both spark performance and flame sensing. Our products are manufactured to tight tolerances for reliable, out-of-the-box performance.

- Broad Configuration & Mounting Options: With a vast selection of threaded mounts (NPT, metric), flange mounts, and custom bracketry, our portfolio supports both OEM equipment and drop-in replacements for field retrofits.

- Compliance with Safety Standards: Our components are designed to meet the rigorous requirements of international safety bodies (such as CSA, UL, and EN), ensuring they integrate seamlessly into your certified safety system.

Applications Across Demanding Industries

Our ignition and flame detection electrodes are trusted by technicians, engineers, and plant managers across Canada’s most demanding sectors:

- HVAC-R & Commercial: Boilers, furnaces, rooftop units, make-up air heaters, and water heaters.

- Power Generation: Duct burners, gas turbine generators, and large-scale utility boilers.

- Petrochemical & Refining: Process heaters, flare stacks, and incinerators where ignition is non-negotiable.

- Industrial Manufacturing: Kilns (ceramic, cement), industrial ovens (drying, curing), and metal treatment furnaces.

- Food & Beverage: Commercial baking ovens, deep fryers, and process dryers requiring precise temperature control.

Installation, Maintenance & Expert Tips (Our Experience)

Proper installation and maintenance are key to longevity.

- Positioning: The ignition electrode must be gapped correctly to the ground source as per the manufacturer’s specification. The flame rod must be positioned to be consistently enveloped by the stable flame, but not so deep that it overheats or becomes coated in carbon.

- Cleaning: Flame rods can become fouled with carbon or other deposits, which insulate the rod and weaken the flame signal. Inspect and clean them regularly with a soft cloth or fine steel wool (do not use sandpaper, as it can score the metal).

- Inspection: Regularly inspect the ceramic insulator for fine cracks, which can absorb moisture and cause a short to ground. Replace any electrode with a damaged ceramic immediately.

Why Trust TriboMarket for Your Combustion Components?

- Expertise: We are more than just a supplier; we are technical specialists. We understand the physics of combustion and the critical role our components play. Our team can help you identify the precise part you need for your application.

- Authoritativeness: TriboMarket is a leading Canadian authority on industrial components. We have built our reputation on sourcing and supplying reliable, high-quality parts for critical infrastructure.

- Trustworthiness: Quality is our promise. Every product is backed by our commitment to performance and customer support. We provide full traceability and stand behind our components with expert technical assistance. We don’t just sell parts; we provide proven solutions.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between an ignition electrode and a flame rod?

An ignition electrode is built to handle very high voltage (thousands of volts) to create a spark. A flame rod is a sensor that operates at a lower voltage and is designed to pass a very small electrical current (micro-amps) through the flame itself. They are generally not interchangeable, though some systems use the igniter for sensing after ignition is complete (a “sense-through-spark” system).

Q2: What causes a ‘flame failure’ shutdown if I can see a flame?

This is almost always a “nuisance shutdown” caused by a weak or non-existent flame signal. The most common causes are:

- The flame rod is coated in carbon or soot.

- The ceramic insulator is cracked, causing the signal to short to ground.

- The flame is not properly enveloping the rod (poor positioning or burner adjustment).

- A bad electrical connection or a faulty ground.

Q3: How often should I replace my ignition and flame electrodes?

This depends entirely on the application, fuel type, and duty cycle. As a best practice, they should be inspected during every scheduled maintenance shutdown (e.g., annually). Replace them immediately if you see significant electrode erosion, heavy pitting, or any cracks in the ceramic. Many facilities replace them proactively every 1-3 years to prevent failure.

Q4: Can I use one electrode for both ignition and flame sensing?

Yes, some specialized electrodes and controllers are designed for this. These are common in compact residential or commercial appliances. However, in most industrial systems, dedicated electrodes are used for each function to ensure robustness and diagnostic clarity.

Find Your Precise Ignition & Flame Solution

Don’t compromise on safety or reliability. A component failure in your combustion system is a critical event. Ensure your system’s integrity with components you can trust.

Browse this page of ignition and flame detection electrodes and contact the TriboMarket technical sales team today. We are here to help you find the exact component for your system and provide a fast, competitive quote.

Reviews

There are no reviews yet.