About Project

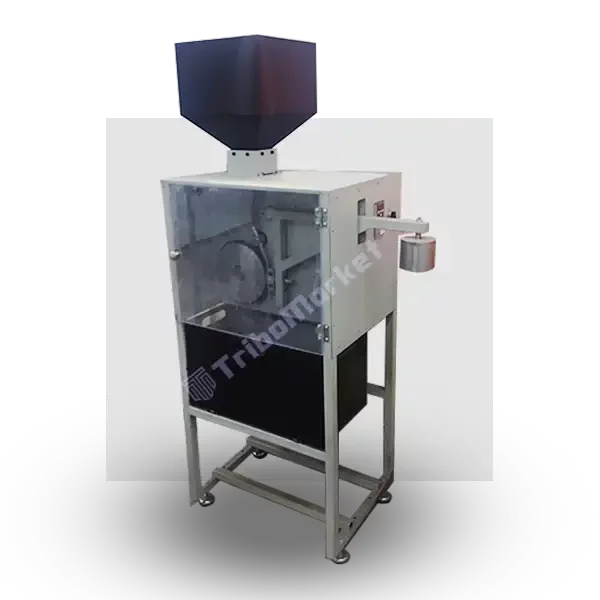

One of the most important devices in the pelletizing industry is the Double Deck Roller Screen, which is responsible for classifying the size of the pellets. According to our observations of the Double Deck Roller Screen of Sirjan Golgohar pelletizing factory, it was found that the most important problems are (Figure 1):

- The amount of input load

- Input load wastes

- Mechanical defects

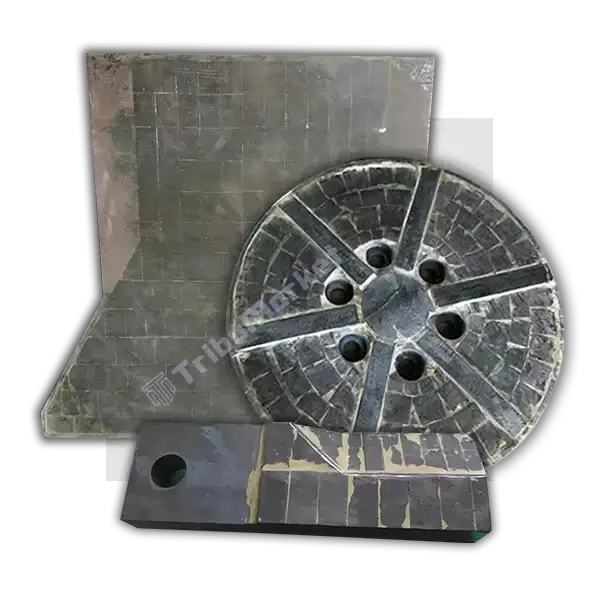

- Quality and type of roll material and its cover

These defects have the following results, which are provided in full below:

- Existence of desirable pellets in return load

- Existence of pellets with out-of-range sizes and stones in the product

- Short life of rolls and housings

- High cost of line stops due to replacement of defective parts

In this project we increased the life of the rolls by modifying the coating and changing the coating of selected rolls areas, which has more wear defect than the rest.

ClientIndustrial Company

Created byTribomarket

CompletedSeptember 2021

SkillsMachinery / Production Line

No comment